-40%

Fanox PBM – Motor Management System: Monitoring, Control & Protection

$ 264.93

- Description

- Size Guide

Description

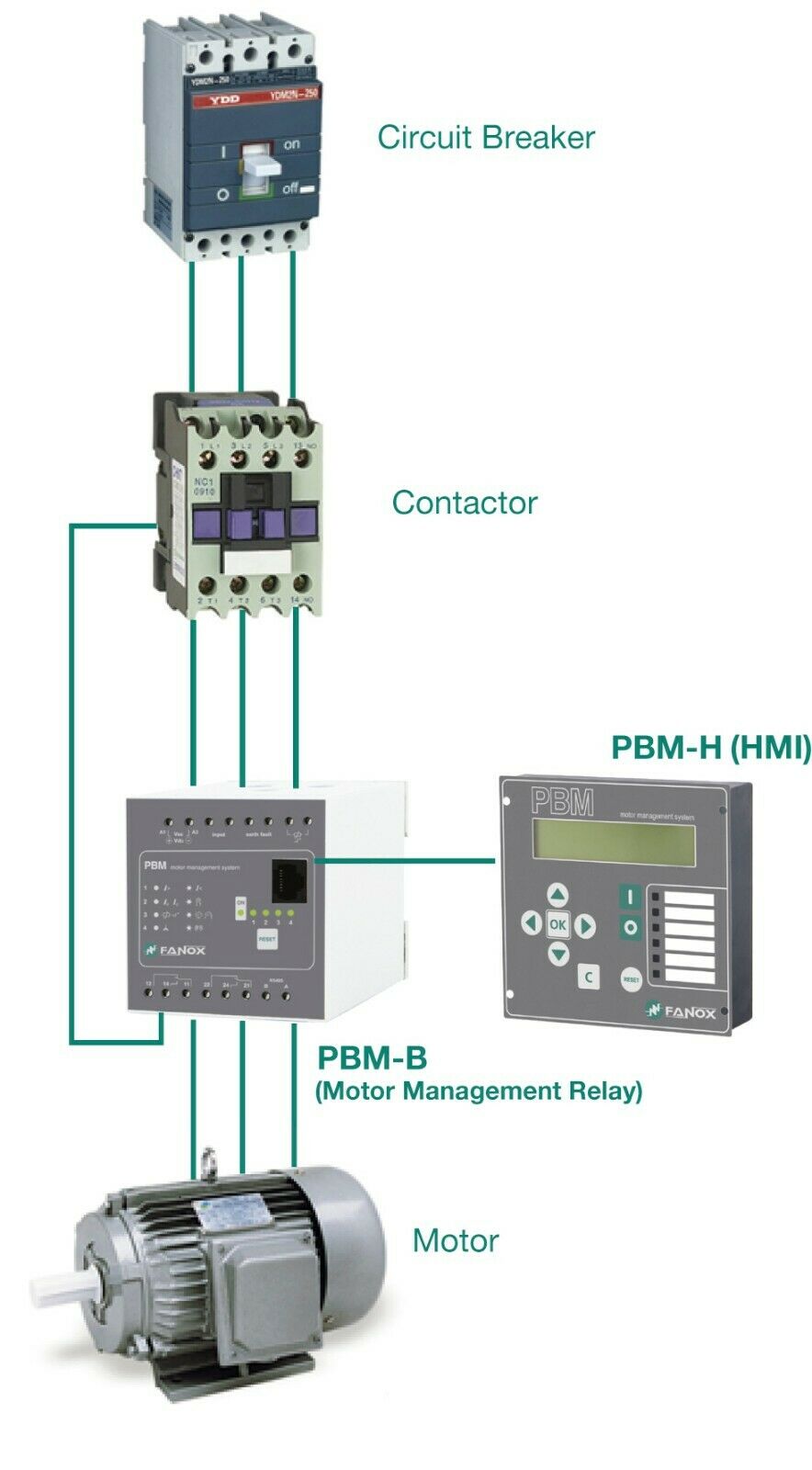

PBM – Motor Management SystemMonitoring, Control and Protection System

, which brings an integral solution to Motor Control Centers. It consists of a Base unit (PBM-B) and a user interface Display Module (PMB-H).

Base Module (PBM-B).

Current measurement is obtained from the motor line through the magnetic module without need of external current transformers from 0.8 up to 25 amp. Over 25 amp, use external current transformers (available through us).

Display Module (PBM-H).

This is an optional display module with an LCD screen for signaling, control, and set-up. The LED indicators can be configured and are identified with labels. Menus are intuitive and direct, making commissioning of the protection system very easy. The display is used for event and fault report analyzing in case of protection trips, current measures, frequency, etc., and for adjusting and setting up the PBM-B module. In addition, a single display can be used in every facility module, thanks to his capability of plugging-in into different PBM-B modules.

Fanox has redesigned PBM to provide new functionality and improve its operability, which makes PBM an indispensable resource for MCCs.

·

Multifunction

·

4 fault reports

·

Self-diagnosis, installation, monitoring and statistics

·

Test menu

·

Designed for SCADA applications

·

Commands management

·

Communication software (PBCom)

·

Protection functions

Protection Functions

·

Overload with thermal image

·

Overheating protection (PTC sensor)

·

Phase imbalance or phase failure

·

Phase sequence

·

JAM detection

·

Locked rotor detection

·

Instantaneous earth leakage overcurrent

·

Earth leakage inverse time overcurrent

·

Instantaneous neutral overcurrent

·

Neutral inverse time overcurrent

·

Undercurrent

Fault Reports

Four (4) fault reports that include: dates, measurements, status bits, inputs and outputs.

Self-Diagnostics, Installation, Monitoring, and Statistics

·

Earth toroidal disconnection monitoring.

·

PTC sensor open circuit and short circuit detection.

·

Magnetic module hardware monitoring.

·

Non-volatile memory stored information coherence.

·

Number of motor starts.

·

Medium and maximum current of last start up.

·

Number of faults for the following functions:

Overload, PTC, JAM, locked rotor and neutral faults.

·

Operating hours counter.

·

Test menu.

Designed For Scada Applications

RTU Modbus protocol and RS485 communication

Commands Management

·

Start/Stop by 2 or 3 wires, without additional switches of push-buttons

·

Remote Start/Stop, more efficiency and cost saving.

Communication software PBCom

The PBCom PC software is used to communicate with Fanox PBM Motor Protection Relay. Software is designed to gain access to PBM relay information, to modify the settings, check states and measurements and to analyze and save events and fault reports using a graphic-friendly user interface.

The main operations that can be carried out using the PBCom software are as follows:

·

General data reading: Complete model, Version, Serial number, etc.

·

States reading

·

Measurements reading

·

Reading and changing settings

·

Reading fault reports

·

Changing the user passwords

·

Saving and Loading settings files

·

Saving fault reports

·

Date-time synchronization

·

Configuring the communication parameters

·

Reading and changing counters

·

Commands for erasing the thermal image

It will allow the user to prepare all the settings and relay configurations without having the relay connected to the PC (offline mode), reducing engineering and commissioning time.

PBCom software uses Modbus protocol, so ports with this protocol are required to establish the communication.

PBM-B BASE MODULE

Product Code

Range

400V Motor

Aux. Supply

110/230 Vac-dc

24/48 Vac-dc

I

B

(Amp)

HP

KW

17000

17002

0.8 - 6

0.33 - 3

0.25 – 2.2

17001

17003

4 - 25

3 - 15

2.2 - 11

PBM-H HMI DISPLAY MODULE

Product Code

Language

17015

Spanish

17016

French

17017

English

17018

Polish

17019

German

* Prices include 3-ft cable to connect PBM-B / PBM-H

Equipment with halogen-free wiring

Fanox specializes in the design and manufacture of electronic relays for Low and Medium Voltage applications.

Since its foundation, back in 1992, Fanox has developed a wide range of products for multiple applications in the low voltage sector, having designed and launched new products to the market every year.

ENERGY CARE TECHNOLOGIES LLC. is distributor of

FANOX products. Contact us for wholesale pricing.